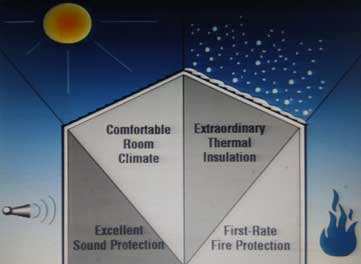

What Gives ECOCON the Competitive Edge?

ECOCON offers strong advantages over conventional building materials because of its exceptional product properties and ease of construction. ECOCON’s excellent strength makes it suitable for both load bearing and non-load bearing structures, and perfect for all types of applications. Although AAC is relatively it has been a favoured building material for over 70 years through out Europe and Asia, and in many countries through out the world.

Fire Safety

- Highest UL fire ratings in the industry provide a fire safe environment

- Product is non-combustible

- No toxins or gases emitted when exposed to fire

ECOCON products are non-combustible. So in the case of fire, ECOCON will help prevent the spread of the fire to other rooms. When exposed to afire, no toxic gases or vapours are emitted from ECOCON products .ECOCON systems such as interior and exterior walls, and in all types of buildings. Single family and multifamily, townhouses, commercial, public and industrial buildings all benefit from the extraordinary fire ratings provided by ECOCON products .ECOCON’s porous structure allows this steam to escape, ECOCON systems can be constructed using blocks, Since these are solid elements, the ease of construction helps to ensure a monolithic, highly fire-resistant.

Excellent Thermal Efficiency

- Thermal performance eliminates insulation

- Reduces Life-Cycle energy costs

- Low heat transfer rate

- Outperforms conventional method and concrete masonry construction

Thermal protection in buildings directly influences the use of energy for heating and cooling, as well as the ability to control the room climate. Less thermal protection results in more energy usage for heating and cooling and a much less comfortable room environment. The thermal protection requirements for the external construction elements of buildings are generally categorized in to one of two groups, either summer or winter. The thermal protection for winter conditions is intended to minimize heat loss from the building, thus allowing the building to be economically heated. The thermal protection properties must, therefore, be determined by considering both criteria .In contrast, the thermal protection for summer conditions is intended to minimize heat gain from the warm outside temperatures and sun rays, thus allowing the building environment to be economically controlled in a comfortable state. Thermal protection in the summer is mainly determined by the capability of the exterior building elements to store and dissipate heat. This property is determined by the mass and thermal conductivity of the building material. With ECOCON, a construction material is available that optimally combines the material properties necessary to provide excellent thermal energy efficiency for the building and healthy indoor environment.

Economic Advantages

- Fast-track construction and fewer finish materials provide a low cost capital option

- No furring, insulation or drywall needed

- Low maintenance costs

Additional Benefits

Product Being light weight, ECOCON Blocks reduces the load on foundation and structures resulting in substantial saving in steel and cement.

- An ECOCON block weighs approximately 50% of a standard brick

- Reduces costs

- Lighter weight product creates easier work environment - less back strain offers safer environment

- Reduced pesticide sprays

- Non-allergenic material results in better indoor air quality – great for asthmatics

- ECOCON can be designed to withstand force winds

- ECOCON is ideal for building in earthquake prone areas also

Flexible Design Options

- Unlimited workability

- Can be sawed, drilled, nailed and milled

- Field adjustments can be made easily

- Block products are available

- An excellent product for all types of climates very hot to very cold

- Pest Resistant

- No voids for insects and pests to make their homes

- Termites will not attack ECOCON products

Acoustic Performance

- Transmission of sound generated from internal sources such as machinery or equipment can be significantly reduced

- Excellent Noise Reduction co-efficient for ECOCON surfaces provides great sound absorption and damping without any additional measures

- Offers more privacy for occupants

- Especially helpful in noise control for buildings such as residential appartments, schools, hospitals, hotels, multifamily housing, and offices Environmentally Friendly

Environmentally Friendly

- ECOCON is an environmentally friendly product made from Fly ash, lime, cement, water, and a rising agent

- No pollutants or hazardous wastes are generated in the process

Energy Savings

ECOCONe AAC blocks also assist in reducing energy costs considerably. Owing to moderated interior temperatures because of its unique properties, the demand on power facilities to heat or cool a room is reduced, leading to lower monthly energy consumption bills. On an average, the savings on cooling an AAC building is well upto 35% compared to constructions made from traditional materials. Thus ECOCON AAC blocks improves the comfort of living for occupant and reduces power consumptions at the same time.

An Energy-Conserving Way to Build

The lightweight properties of ECOCON autoclaved aerated concrete products are also very favourable characteristics for the environment. Energy consumption and costs for delivering ECOCON products to the project site are reduced due to ECOCON’s light weight. The manpower and equipment required to install ECOCON building systems can be efficiently utilized in all phases of construction. The ease in which the material is cut, shaped and placed allows for easy fit up with less physical energy consumed .ECOCON’s high insulating properties ,which surpass most other building products, also provide on-going energy savings for the building owner by increasing the building’s thermal efficiency.

Regulated Internal Temperature

Buildings constructed with AAC tend to be cooler in summer and warmer in winter as compared to clay or fly ash bricks. As a result, with the use of ECOCON AAC blocks, the air conditioning or heating required for interiors is reduced and further makes the use of additional thermal insulation unnecessary. ECOCON AAC blocks also are better than fly ash bricks. Although an eco-friendly material, fly ash bricks absorb more heat, making the temperature much warmer.

Improved Indoor Air Quality

Considering that most of the time is spent indoors, it is essential to ensure healthy quality of air for the occupant. ECOCON AAC block material that contains no toxic substances and does not decompose or off-gas. This maintains better quality of indoor air.

ECOCON’s Uses - Safe and Healthy for the Environment

-

The exceptionally good thermal insulation property of ECOCON sets the standard for energy conservation, which reduces the generation and emission of CO2.Due to its purely mineral composition, ECOCON is non-combustible and no toxic fumes are generated. ECOCON also provides a comfortable environment due to its good sound insulation in buildings.

ECOCON is available in several different load bearing and non-load bearing forms:

- Large blocks: which can be quickly and easily placed with thin bed mortar.

- Lightweight wall Partitions: They can be used in single and multi-story buildings and are ideal for residential, commercial, educational, industrial and public buildings.

Construction Benefits

- Fast and efficient Block reduces labour cost

- Modular components provide for ease of erection

- ECOCON AAC puts your project on the fast track

- No furring, insulation or drywall needed

- Superior thermal insulation of ECOCON Blocks makes it comfortable for the occupants. It results in lower electricity cost due to reduced air-conditioning loads.

- Decrease in number of joints and accurate dimensions of blocks result in reduced cement mortar, plastering and labour.

- Optimum width results in increased carpet area when compared to brick walls.

Tremendous Benefits for Everyone

AAC building systems have been successfully developed and implemented for more than 65 years. They have been utilized in residential and commercial applications.

The short- and long-term benefits of these systems are realized by owners, developers, designers and contractors alike. The benefits are achieved by the various material properties and methods that are associated with the established ECOCON approach to construction.

-

For the Owner

One of the main benefits of ECOCON is safety. An owner using ECOCON products creates a sound, functional and safe building. Another benefit of the ECOCON system is versatility. ECOCON can provide many architectural features that will enhance and project a unique architectural image for the building and its owner. ECOCON construction is insect and termite proof. Therefore, the need for expensive insect and pest treatment as well as long term maintenance costs will be greatly reduced. To complete ECOCON's concept of a great building system, the superior thermal properties associated with all of the ECOCON products will translate into increased energy savings.

-

For the Developer

The cost savings realized when using ECOCON products, mainly related to the shorter construction time, will be dramatic. The advantages of ECOCON include low maintenance costs, good sound insulation and excellent thermal insulation.

-

For the Designer

Creative designs cannot be realized without the use of a highly adaptable construction material. ECOCON can be adapted to suit most architectural designs while still providing a simple construction system that can meet all requirements.

-

For the Contractor

Buildings can be constructed quickly and safely using ECOCON building systems. The product itself is lightweight; therefore, easily handled.

ECOCON's workability (e.g. anchoring, routing, and drilling characteristics) is well developed and can be easily performed. Typically, wall panel connections are installed with nails. ECOCON material also produces less waste. By using the right combinations of ECOCON products, productivity will be increased. ECOCON will reduce the amount of time spent on job sites due to its ease of handling.

LAYING OF AAC BLOCKS

- The jointing mortar shall be leaner i.e., 1:6. The mortar shall not be spread so much ahead of the actual laying of the units that it trends to stiffen and loose its plasticity there by resulting in poor bonding.

- Consistency as per requirement of site must be maintained at the point of laying.

- Laying of light weight Blocks masonry shall be in accordance with the recommendations of IS 6041 of 1985 and IS 1905 of 1987. The maximum joint thickness (Vertical and Horizontal) shall be 10 – 12 mm.

- Laying of AAC Blocks masonry shall be in accordance with the recommendations of IS 6041of 1985 and IS 1905 of 1987.The maximum Joint thickness (vertical and Horizontal)shall be 10-12mm

- The laying ofblock may be started either at the corners first or it may be started from one end and proceed to the other direction.

- Lay 10 mm thick cement mortar uniformly over bed. Wet the block on all sides by using a tray filled 20/25 mm water and place them one by one and press it firmly to have proper bond. Ensure proper spread of mortar in in the joints between the blocks.

- The first course of the cellular block masonry shall be laid with great care, making sure that it is properly aligned, leveled and plumbed, as this may assist the mason in laying succeeding courses to obtain a straight and truly vertical wall.

- Ensure all the surface of the block which comes in contact with the with cement mortar are wet to have proper bonding.

- To maintain proper cement mortar filling at the still level, please check the height of masonry and distribute the same along the joints and if the gap is more same can be adjusted in the bedding mortar. Later the joint shall be ideally filled up with jute strips dipped in cement slurry so that flexible can be maintained at that level.

- Before laying the mortar, two 10 mm square rods can be placed on both sides of the block to obtain uniform joint.

- The mortar joint shall be struck off flush with wall surface and when the mortar stiffening, it shall be compressed tightly.

- Once the masonry erected the curing shall be minimum unlike brick masonry.

- The curing requires more at the joints.

- Before plastering cement slurry shall be applied on the walls and only leaner mix shall be applied. The thickness shall be 10-12 mm in the external walls and in the internal application in case of dry walls plastering can be avoided. In such case directly P.O.P/ Gypsum plaster can also be applied.

- Maximum erection of 5-6 courses is desirable in a day.

CHASING AND CUTTING

- Blocks shall be cut with a saw.

- Where ever chasing to be done in light weight blocks, rotary cutters can be used. The chases shall be refilled with leaner mortar and chicken mesh (as per consultant’s recommendations) shall be applied on the area.

Conclusion

All these factors relate to cost, time and labour savings for the project. These factors epitomize ECOCON's commitment to expediting construction, cost effectiveness and an aesthetically appealing building system.